Clamp, rotatable OT60.17

Prices visible to registered customers onlyClamp, Rotatable OT60.18

Prices visible to registered customers onlyClamp, Easy Fix OT60.15

Prices visible to registered customers onlyClamp, Standard OT60.16

Prices visible to registered customers onlyClamps for operating tables – The inconspicuous centerpiece of surgical flexibility

Clamps for operating tables are inconspicuous but indispensable connecting elements in every operating room. They are used to securely attach accessories such as arm supports, cushions, supports or holding systems to the operating table. Without them, flexible working in the OR would hardly be possible, because the clamp is the link between the table and the surgical accessories. A modern operating table is designed in such a way that it can be individually adapted to the procedure and the patient’s situation. The clamp ensures that this adjustment is quick, safe and hygienic. It is simply attached to the side standard rail of the table and fixes the accessories in the desired position – stable, without wobbling and with high holding power.

Clamps from Inspital GmbH stand for precision and quality. They are made of high-quality stainless steel, are corrosion-resistant and meet the high hygiene requirements in the OR area. Thanks to their ergonomic design, they are easy to use even with gloves and offer reliable fixation, even under time pressure. Whether in general surgery, orthopedics or neurosurgery – clamps for operating tables guarantee maximum safety and efficiency. They enable doctors and nursing staff to position patients precisely, increase work ergonomics and contribute to smooth operating procedures. A high-quality clamp may seem small, but it fulfills a large task: It holds everything in place when it matters.

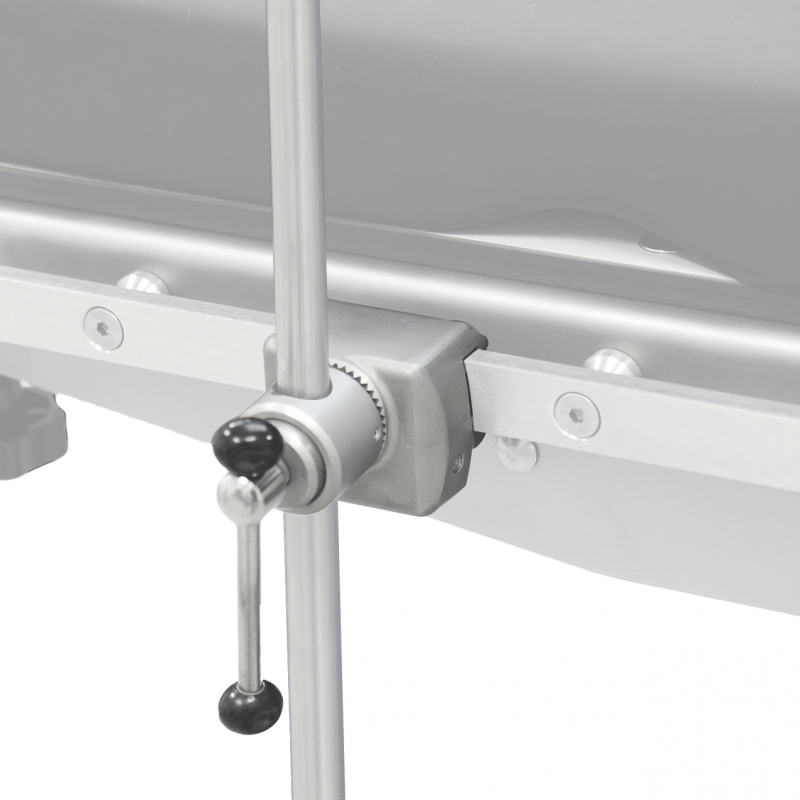

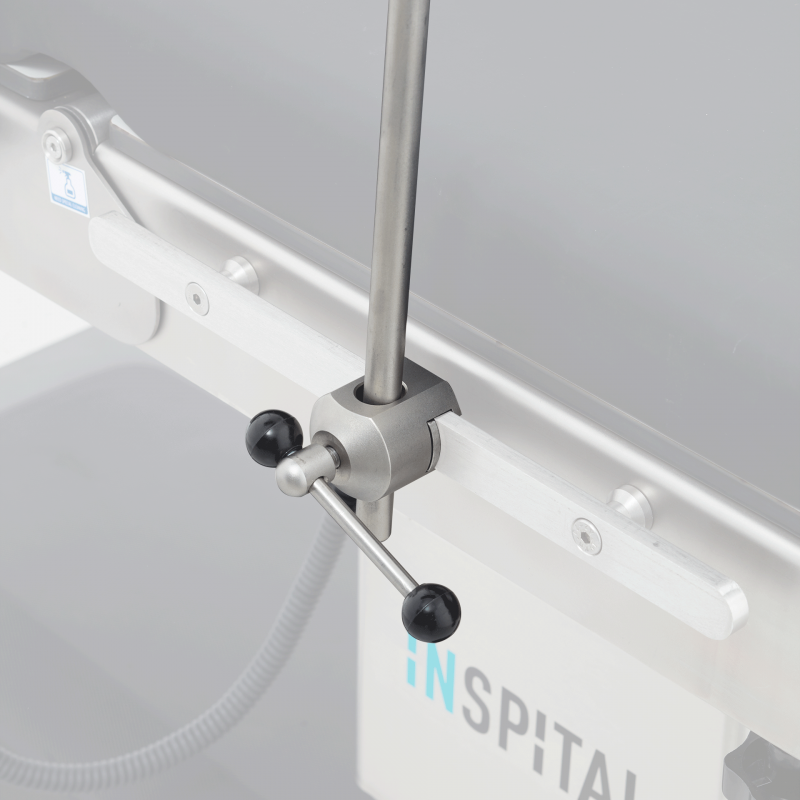

Structure and function of a clamp for operating tables

A clamp for operating tables usually consists of a stable base body with a screw or quick-release mechanism. It is attached to the table rail and enables the attachment of positioning and holding elements. The combination of stability and ease of use is crucial.

Most operating tables have standardized rail dimensions, so clamps can be used universally. Inspital GmbH offers models with precise tolerances that are perfectly matched to these standards. This ensures a secure hold – regardless of the weight or position of the accessories. Modern clamps have quick-release systems that allow one-handed operation. This allows OR personnel to change accessories in seconds without interrupting the sterile workflow.

The functional principle is simple but effective: the clamp is placed on the rail, fixed and then provides a stable mount for accessory arms, supports or cushions. Thanks to the precise construction, the position of the accessories remains constant even under heavy loads – a crucial factor for safety and precision in the OR. A well-thought-out design, such as that offered by Inspital, reduces maintenance and increases service life. This turns a simple fastening part into a durable, safety-relevant tool for daily clinical operations.

Safety and stability – Why clamps are indispensable in the OR

In the operating room, every movement counts – and every bracket. Clamps for operating tables are crucial for securely fixing accessories and keeping the patient’s position stable. Even the smallest movements can make the procedure more difficult or increase the risk of complications. That is why the quality of the clamps plays a central role. They must withstand high loads, remain vibration-free and at the same time enable quick adjustment. Inspital GmbH relies on precision-manufactured stainless steel components that remain reliable in intensive use. A high-quality clamp not only ensures stability, but also safety. Its mechanism prevents unintentional loosening, and its material is resistant to corrosion and frequent sterilization.

In addition, an ergonomic design makes handling easier – especially important when accessories need to be changed quickly in hectic OR situations. In short: A clamp is more than a connecting element – it is a safety component. Without it, precise and safe positioning of the patient in the OR would not be possible.

Materials and hygiene requirements for clamps for operating tables

The requirements for materials in the OR area are extremely high – and clamps are no exception. They must be durable, hygienic and easy to clean. Inspital GmbH relies on stainless steel, which is specially suitable for medical applications. Stainless steel not only offers stability, but also resistance to disinfectants, steam sterilization and corrosion. These properties guarantee a long service life and absolute hygiene.

The surfaces of the clamps are smoothly polished to prevent deposits or dirt. Each contact point is designed to remain easily accessible and easy to clean – a crucial advantage for sterilization processes.

In addition to stainless steel, some components also use anodized aluminum parts or medically approved plastics when weight needs to be reduced. This combination of material quality and precision manufacturing creates clamps that meet the highest standards – robust, hygienic and reliable, even after thousands of cycles in everyday OR use.

Types of clamps for operating tables – Flexibility for every application

Depending on the surgical discipline, different types of clamps are required. Inspital GmbH offers a wide selection to meet the individual requirements of every clinic.

Quick-release clamps – allow accessories to be attached and detached with just one hand. Ideal for frequent changes in the OR.

Radial adjustment clamps – offer maximum mobility, e.g. for the exact positioning of arm or leg supports.

Screw clamps – particularly stable and resilient, suitable for heavy accessories.

The right choice depends on the area of application. In orthopedics, particularly resilient clamps are required, while in plastic surgery, precision and fine adjustment options are paramount. A universal design ensures that Inspital’s clamps are compatible with common operating tables and accessory systems – an advantage for clinics that value efficiency and flexibility.

Purchase advice – What to look for in a clamp for operating tables

When buying a clamp for operating tables, precision, compatibility and ease of use are important. It is crucial that the model fits the standard rail of the operating table and securely holds the required accessory arms.

Another criterion is handling. Models with quick-release systems save valuable time and are particularly ergonomic. Material quality is just as important – stainless steel is standard here, as it is durable and hygienic.

Clinics should also pay attention to ease of maintenance: clamps with few individual parts can be cleaned and reassembled more quickly. Inspital GmbH offers products that are precisely tailored to these requirements – safe, robust and intuitive to use. If you think long-term, you should invest in high-quality clamps. They not only guarantee more safety, but also reduce operating costs due to their durability.

Maintenance and service life – How to keep clamps permanently reliable

In order for clamps for operating tables to function precisely in the long term, regular maintenance and proper cleaning are essential. After each use, all parts should be thoroughly disinfected and visually checked for wear.

Inspital recommends regularly lubricating moving components and checking screw connections for a tight fit. This ensures that the clamping force and holding stability are permanently maintained.

Clamps made of stainless steel can be autoclaved without any problems without impairing their function. However, it is important to avoid aggressive cleaning agents that could attack surfaces.

Consistent care significantly increases the service life – a clear advantage for clinics that rely on sustainable, reliable medical technology. A well-maintained clamp remains safe, hygienic and precise for many years – day after day in use for patient safety.