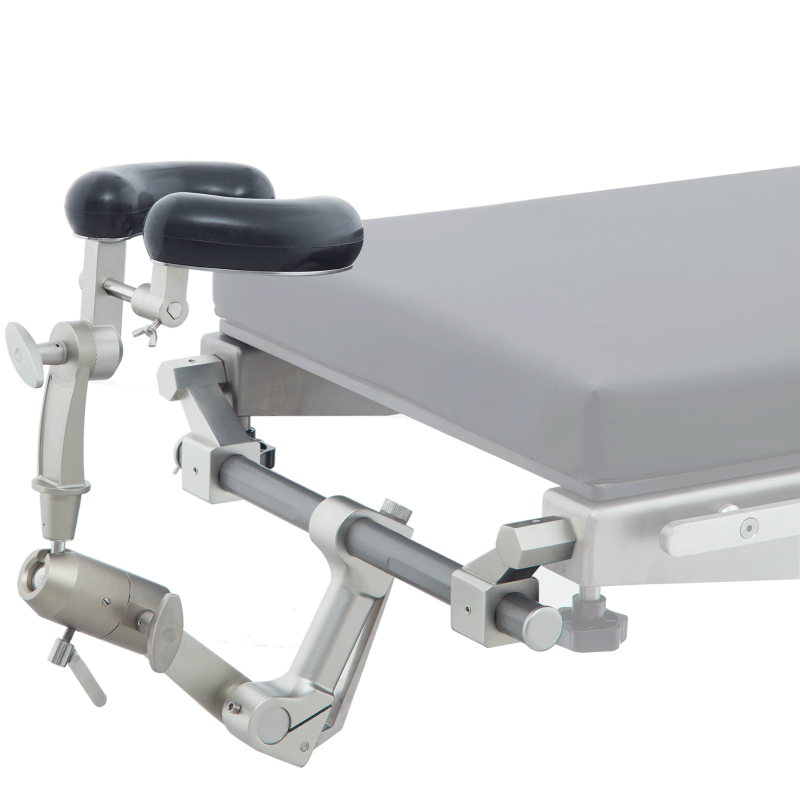

Neurosurgical Head Rest with Pin & Horseshoe Head Rest OT60.80

Prices visible to registered customers onlySkull Clamp – Precise Fixation for Maximum Safety in Neurosurgery

The skull clamp is an indispensable instrument in modern neurosurgery. It enables the exact fixation of the head during delicate procedures on the brain, skull, or cervical spine. Stable head positioning allows surgeons to work precisely without the risk of unintentional movements. High-quality skull clamps are usually made of robust stainless steel or titanium and feature three-point fixation pins that securely stabilize the head. Inspital GmbH develops skull clamps that excel through ergonomic design, precise mechanics, and high-quality materials. The clamp’s pins distribute pressure evenly, ensuring the head is fixed without damaging tissue. At the same time, the clamp allows for fine adjustments in all directions, enabling the surgeon to set an optimal position for surgical intervention.

Inspital skull clamps are compatible with common operating tables and modular holding systems. They facilitate integration into existing surgical workflows and improve work efficiency. In combination with radiolucent tabletops or imaging systems, a setup is created that guarantees maximum precision, safety, and flexibility. A skull clamp is therefore much more than just a holding system – it is a crucial tool that directly supports the success of operations and increases patient safety.

Structure and Function of a Skull Clamp

A skull clamp is a fine mechanical precision instrument specifically designed to securely fix the patient’s head during surgical procedures. It consists of a stable base frame, three or more support arms, and a finely adjustable clamping mechanism. The base frame serves as the connection to the operating table or holding arm. Inspital skull clamps are designed to be securely mounted on common table systems while also being easily detachable when different positioning is required.

The support arms, also known as pins, grip the skull precisely and distribute pressure evenly. This prevents pressure points and minimizes the risk of tissue damage. Thanks to precise adjustment, the head can be moved in all directions – up, down, sideways, or tilted – while maintaining stability. The clamping mechanism is the core of the skull clamp. Inspital relies on fine mechanical systems that enable millimeter-precise fixation. Operation is ergonomically designed, allowing surgeons to quickly position the head without leaving the sterile field.

Skull Clamp: Safety and Stability – Indispensable in the OR

The skull clamp plays a central role when it comes to safety and stability during neurosurgical procedures. Even the slightest head movements can jeopardize the success of an operation and increase risks for the patient. Therefore, precise and secure fixation is essential. Inspital skull clamps distribute pressure evenly across multiple contact points. This design prevents pressure points on the skull while ensuring maximum stability. Mechanical safeguards guarantee that the clamp remains firmly in place throughout the entire procedure, even when instruments or imaging systems are moved. Additionally, the clamp allows for exact fine adjustment. Surgeons can position the head with millimeter precision in all directions: sideways, vertically, or tilted. This is particularly important for complex procedures on the skull base or spine.

The stability of the skull clamp not only reduces risks but also supports the ergonomics of the surgical team. Surgeons can concentrate on their work without constantly having to correct the patient. At the same time, anesthesia and nursing staff benefit from secure head positioning, which makes the entire surgical workflow more efficient. In combination with modern operating tables, carbon fiber tabletops, or imaging systems, a high-quality skull clamp ensures the optimal balance of safety, stability, and flexibility. Inspital GmbH relies on materials, mechanics, and design that meet the highest demands of neurosurgery.

Skull Clamp: Materials, Workmanship, and Hygiene Requirements

The choice of material is crucial for the function and longevity of a skull clamp. Inspital GmbH relies on stainless steel, titanium, and medically approved alloys. These materials are corrosion-resistant, resistant to disinfectants and sterilization processes, and guarantee a long service life.

The surfaces are smoothly polished to prevent deposits and facilitate cleaning. All movable parts are robustly constructed so that the clamp retains its precision even after frequent use. High-quality workmanship minimizes mechanical wear and ensures that the clamp functions reliably under all conditions. Hygiene requirements play a central role. Inspital skull clamps can be completely disassembled and autoclaved. The materials do not react to heat or cleaning agents, minimizing the risk of germ transmission. The combination of high-quality materials, precise workmanship, and optimized surface structure ensures that the skull clamp meets the highest safety and hygiene standards in the OR. Thus, it remains reliable even after many years and provides a safe working environment for surgeons, nursing staff, and patients.

Areas of Application and Flexibility of the Skull Clamp

A skull clamp is used in numerous areas of neurosurgery:

Brain Surgery: for stable positioning during tumor operations or vascular repairs.

Spinal Surgery: for procedures on the cervical spine or skull base.

Traumatology: for precise fixation in cases of cranial and head injuries.

Image-Guided Procedures: compatible with X-ray, CT, and other imaging systems.

Inspital GmbH manufactures skull clamps that are modular and versatile. They can be mounted on various operating tables, allow for quick position changes, and support imaging systems without repositioning the patient.

The clamps are suitable for different head sizes and shapes. Fine adjustment allows pins to be precisely positioned, so both adults and children can be securely fixed. The flexibility and versatility make the skull clamp a central tool in every neurosurgical facility. It combines stability, precision, and adaptability, thereby increasing efficiency and safety in the OR.

Purchase Criteria for a High-Quality Skull Clamp

When purchasing a skull clamp, several factors play a central role, as they directly influence safety, precision, and efficiency in the OR.

Material and Workmanship: High-quality stainless steel, titanium, or medical alloys ensure stability, corrosion resistance, and longevity.

Compatibility: A clamp must be adaptable to common operating tables and holding systems.

Ergonomics and Ease of Use: Finely adjustable support arms and intuitive clamping mechanisms facilitate precise head positioning, even under sterile conditions.

Flexibility: The clamp should be suitable for different head sizes and surgical applications. Inspital skull clamps can be adjusted with millimeter precision to ensure optimal positions for various procedures.

Maintainability: Autoclavable parts, easily accessible screws, and wear-resistant mechanisms facilitate cleaning and maintenance, increase service life, and reduce operating costs.

Safety: High-quality clamps feature safeguards against unintentional loosening, ensuring that fixation remains guaranteed throughout the entire procedure.

Maintenance, Care, and Service Life of a Skull Clamp

The maintenance and care of a skull clamp are crucial for precision, safety, and longevity. Inspital GmbH recommends a structured approach to ensure continuous functionality.

Cleaning and Sterilization: After each use, the clamp and pins should be thoroughly cleaned and autoclaved. The materials of Inspital skull clamps are resistant to heat, moisture, and disinfectants, ensuring sterility is guaranteed at all times.

Mechanical Inspection: Before each operation, screws, pins, and clamping mechanisms should be checked for a secure fit. Movable parts must function smoothly to guarantee secure fixation.

Lubrication and Care: If necessary, movable parts can be lightly oiled to keep the mechanics smooth and reduce wear. Regular inspection prevents loss of function and extends the service life.

Durability and Investment Protection: High-quality materials such as stainless steel or titanium ensure that the clamp remains stable even after numerous sterilization cycles. Hospitals save costs in the long term through minimal maintenance and reduced replacement procurement.

Efficiency in the OR: A well-maintained clamp increases safety, reduces interruptions, and facilitates the work of the OR team. It ensures stable fixation, precise positioning, and optimal patient safety.