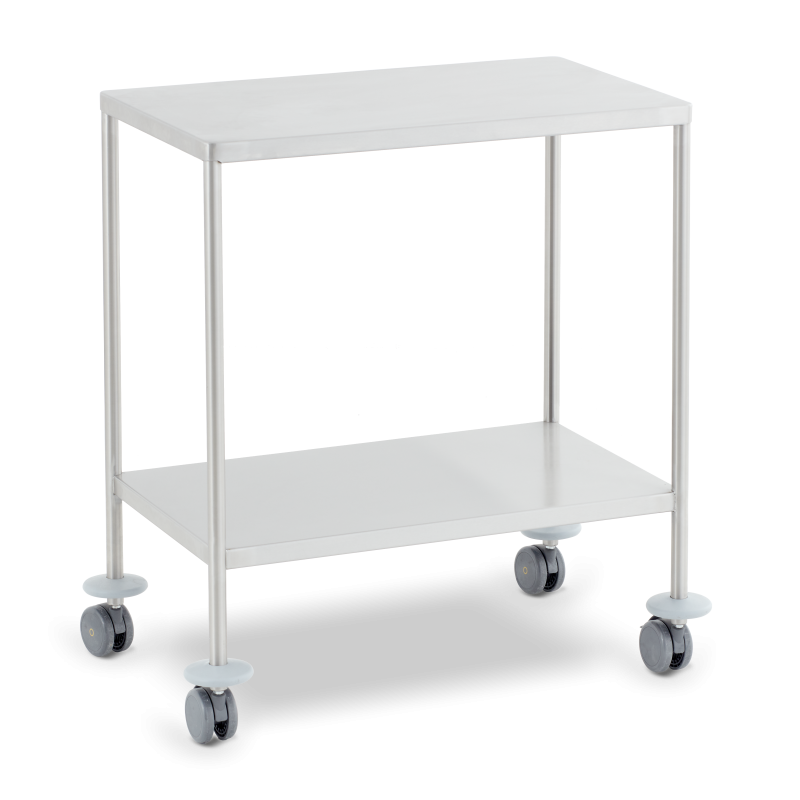

Instrument Trolley AB00.21

Prices visible to registered customers onlyHydraulic Mayo Table MS10.51

Prices visible to registered customers onlyInstrument Trolley: Why a High-Quality Instrument Trolley is Indispensable in Hospitals

An instrument trolley is an indispensable tool in every hospital. It forms the basis for order, efficiency, and hygiene in daily clinical operations. In operating theaters, emergency rooms, nursing departments, or treatment rooms, the trolley ensures that medical instruments, consumables, and sterile products are always readily available. The most important advantage of a high-quality instrument trolley is the optimization of workflows. When doctors and nursing staff can quickly and safely access all necessary instruments, the preparation time for procedures is significantly reduced. At the same time, sources of error are reduced, as each tool has its designated place. Especially in hectic situations – such as during an operation or in emergencies – clear organization is crucial.

Another factor is hygiene. Instrument trolleys are usually made of stainless steel or powder-coated aluminum. These materials are not only stable but also easy to clean and disinfect. This allows them to meet the high demands for sterility in hospitals. Modern models are also equipped with rounded edges, smooth surfaces, and special grip zones to prevent dirt accumulation. Mobility also plays a central role. Instrument trolleys are equipped with high-quality castors that allow for easy and safe movement between treatment rooms, wards, or operating areas. This keeps medical staff flexible and allows them to use materials where they are needed.

Last but not least, instrument trolleys contribute to a professional overall impression. Order and cleanliness build trust with patients and facilitate the work of staff. In short: a well-designed instrument trolley is not just an aid, but a crucial component for efficient, safe, and hygienic hospital operations.

Construction and Features of Modern Instrument Trolleys

A modern instrument trolley for hospitals is far more than just a mobile table. It is a complex, well-thought-out system specifically tailored to the demands of daily medical practice. Depending on the area of application, the construction can vary greatly – but certain features distinguish high-quality models.

The frame is usually made of stainless steel, which guarantees not only stability but also durability. Stainless steel is corrosion-resistant, easy to clean, and meets all hygiene standards. Alternatively, anodized aluminum frames are also used, which are particularly lightweight yet robust.

The shelves are often height-adjustable and feature an anti-slip coating. Some models offer additional drawers, compartments, or removable baskets to neatly organize materials. In operating theaters, instrument trolleys with removable trays are often used, which can be sterilized after use.

The castors are particularly important: High-quality instrument trolleys have ball-bearing swivel castors, at least two of which are equipped with locking brakes. This ensures the trolley remains securely in place when needed. Models with electrically conductive castors also prevent static charge – a detail that is essential in sensitive operating areas.

Many manufacturers now also offer modular systems where the construction, drawer division, or accessories can be individually adapted. This allows hospitals to precisely tailor each trolley to the respective specialist area – whether surgery, intensive care, gynecology, or emergency room.

In short: The construction of a modern instrument trolley combines functionality, ergonomics, and hygiene – three factors that are crucial for ensuring smooth workflows in hospitals.

Instrument Trolley: Materials and Hygiene Requirements in Hospitals

In a hospital, hygiene is the top priority. This particularly applies to all equipment and furniture that regularly come into contact with medical instruments and materials. Therefore, the choice of the right material for instrument trolleys plays a central role.

Stainless steel is considered the preferred material in hospital environments. It is not only durable but also germ-resistant and easy to clean. The smooth surfaces prevent bacteria from adhering, and even aggressive disinfectants cannot harm the material. Furthermore, stainless steel does not rust and remains hygienically flawless even after years of continuous use. Alternatively, aluminum or high-quality plastics are used. These materials offer the advantages of low weight and high stability. However, it is important that they are resistant to disinfectants and free of porous structures where germs could accumulate.

Another hygiene factor is the design of the instrument trolley. Rounded edges, concealed welds, and seamless transitions facilitate cleaning. Removable drawer inserts or detachable shelves allow for thorough sterilization after each use. Furthermore, clear material separation is important: sterile and unsterile utensils must be stored separately. Many instrument trolleys therefore feature modular systems that enable strict organization of their contents.

Through this combination of high-quality materials, thoughtful design, and easy cleaning, the instrument trolley actively contributes to meeting high hygiene standards in hospitals and sustainably reducing the risk of infection.

Instrument Trolley: Areas of Application and Function in Daily Clinical Practice

An instrument trolley is a true multi-talent in hospitals. Whether in the operating theater, intensive care, outpatient area, or on the ward – it is used wherever medical materials need to be quickly and safely available. In the operating room, the trolley serves to keep sterile instruments organized and ready. Surgeons and scrub nurses can thus work efficiently during the procedure without losing time. After the operation, the trays can be easily removed and taken for sterilization.

On wards, however, the instrument trolley is often used for nursing tasks or wound care. Here it contains dressings, disinfectants, syringes, or catheters. Thanks to its mobility, it can be moved from room to room – a clear advantage for an efficient care concept. The instrument trolley also has a fixed place in the emergency room. In acute cases, materials such as cannulas, swabs, or surgical instruments must be readily available within seconds. A structured trolley helps to defuse stressful situations and maintain an overview.

Even in laboratories or specialized departments such as endoscopy or cardiology, the trolley facilitates daily work. It ensures organization, cleanliness, and efficiency, regardless of the area of application. Thus, it is a universal tool that should not be missing in any medical facility.

Instrument Trolley: Ergonomics and User-Friendliness

In a modern hospital, time is a crucial factor. Every action counts, every second can make a difference – be it in the operating room, in the intensive care unit, or in daily ward routine. That is precisely why the ergonomics of an instrument trolley are so important. Inspired by the daily demands of medical staff, high-quality models are now developed to optimally support workflows while reducing physical strain. An ergonomically designed instrument trolley impresses with intelligent details: rounded edges, smooth-running castors, intuitive grip positions, and perfectly balanced weight distribution. The work surfaces are often height-adjustable, allowing doctors and nursing staff to work in a natural posture, both standing and sitting. This significantly reduces back pain, shoulder tension, and poor posture – a crucial factor for the long-term health of the staff.

User-friendliness also plays a central role. Drawers with soft-close systems open and close quietly and with minimal effort. The arrangement of compartments follows a logical structure: frequently needed instruments are at grip height, less frequently used materials in the lower area. This intuitively supports the workflow, eliminating the need to constantly search for tools. In addition, most instrument trolleys are equipped with ergonomic handles and stable pushing elements, which facilitate maneuvering even in confined spaces or long hospital corridors. Low-noise castors ensure silent, smooth pushing – an aspect that is particularly advantageous during nocturnal rounds on the ward.

The psychological component should not be underestimated: A thoughtfully designed, comfortable trolley not only increases efficiency but also job satisfaction. When processes run smoothly and handling is effortless, this positively impacts motivation and team performance.

Instrument Trolley: Care, Cleaning, and Maintenance

In no other industry does hygiene play as significant a role as in healthcare. An instrument trolley that daily comes into contact with medical devices, dressings, or sterile instruments must therefore be easy to clean and disinfect. Regular care and maintenance not only determine the lifespan of the trolley but also compliance with hygiene standards in the hospital.

High-quality models are made of stainless steel or anodized aluminum, as these materials offer smooth, non-porous surfaces. Dirt, dust, or germs can hardly accumulate here. Daily cleaning should be performed with a disinfectant-resistant cloth and approved cleaning agents. It is particularly important that all corners, edges, and grip areas are thoroughly treated. Many manufacturers design their instrument trolleys so that there are no hard-to-reach areas – welds are sealed, transitions are seamless, and the wheels can be easily disassembled for separate cleaning. This reduces the risk of germ accumulation and makes the trolley hygienically safe.

Regular technical maintenance also contributes to value retention. Castors and brakes should be checked regularly, hinges and joints lightly oiled, and loose screws tightened. A monthly visual and functional inspection is recommended to ensure that the trolley remains ready for use at all times.

Instrument Trolley: Economic Efficiency and Investment Benefits

An instrument trolley is a strategic investment in quality, safety, and economic efficiency. While a high-quality model may initially seem more expensive than a simple variant, practice quickly shows that this acquisition pays off many times over in the long run. A crucial factor is durability. Robust stainless steel trolleys can be used for many years without losing stability or functionality. This means: fewer repairs, lower replacement costs, and a significantly longer service life. Furthermore, stainless steel is virtually indestructible, resistant to chemicals, and easy to maintain – ideal conditions for continuous operation in a hospital.

The time savings through efficient organization also directly impact economic efficiency. If nurses or doctors do not constantly have to search for materials, they save valuable minutes daily. Calculated over a year, this can amount to many hours of working time – time that can be better used for patient care. Furthermore, ergonomic, easy-to-use trolleys reduce sources of error and material losses. Instruments and consumables remain protected, are stored correctly, and are always readily available. This increases not only productivity but also safety in daily work.

Another economic aspect is energy and resource efficiency. Due to the high material quality, the frequent need for replacement is eliminated, reducing environmental impact and procurement costs. Many hospitals today consider the life cycle of a product – and here, high-quality instrument trolleys perform significantly better than cheap models.